When people ask you about a woodworking factory in Indonesia, what does it come to your mind? Does it represent any type of old factory that produces lots of wooden furniture that you can possibly find in the house? Does it only provide raw materials or building support but not the inside interior? Believe it or not, some woodworking factories only focus on producing one special kind of product because to make a piece of work; they need to complete several regulations, steps, and preparation. As a result, producing multiple products that are different from one another is unlikely because it means that the factory needs to provide more machinery, labor, and materials; and only large companies can do this kind of this, although most of them will hire a subcontractor to create a product under their name.

Table of Contents

Woodworking Factory in Indonesia For Doors

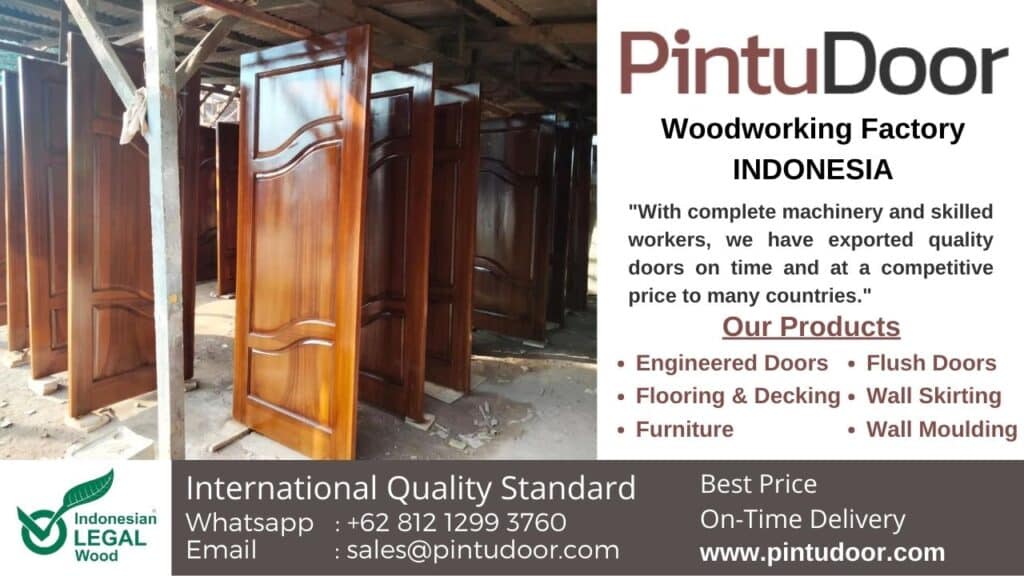

It is common to find woodworking factories that only produce doors and nothing else; other factories may concentrate on producing other interior and exterior necessities such as cabinets, windows, floors, and many more. There is the reason why specialization of each factory is needed, and the reason is that the technology behind the productions is already installed into the machinery. The installation of the software and program usually applies to cutting the materials and providing any supporting materials to create a product.

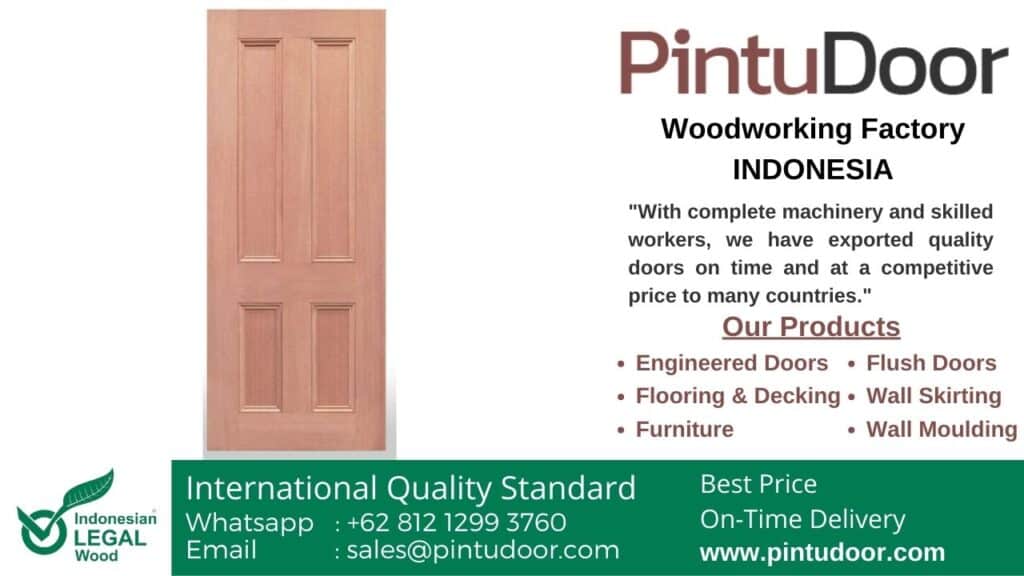

When the woodworking factory in Indonesia only produces wooden flush doors and solid engineered doors, it doesn’t mean that they will manufacture all kinds of doors that you can think of. Most of them only produce several types of doors that use the same materials; often, they only produce one single type of door but different in colors. The program and machine that are used to produce a product are quite sensitive, and it is unlikely that the factory will regularly change the system of the machine to create new products. It’s the reason why each factory only focuses on one single type of production.

As woodworking factories specialize in single products, they can also produce the product in mass production as they don’t really have to be worried about production type. Manufacturing a single type of product will allow producing more products because there is a limited approach to completing the products, and there will be fewer errors during production because the laborers have already mastered their job tasks.

What If The Factory Decide To Change The Design Of Their Product? Do They Have To Change Their Entire System?

Basically, a woodworking factory can do innovation in terms of design and any other aspects of production. Although the machinery seems to be inflexible, it can be used for different purposes; buying a flexible machine is considered an early investment for the factory because they want to avoid changing the machine regularly or when they have to make slight changes.

When the company wants to change the design of the door, the first thing they do is to create a prototype that shows the whole product. Prototyping is crucial because sometimes the picture can look better than the actual product, so creating a prototype will make sure the owner whether they can mass produce the product or not.

After creating the prototype, the factory needs to adjust the machine, and some machinery software may record hundreds of system that helps the factory produce a product. After adjusting the machine and the program then, the factory needs to introduce a new task for each of the laborers; they need to train them and support the labor during the first semester of production to make sure that each of them is mastering their job task.

Woodworking factories, whether they are big or small companies, usually only focus on producing one single product because creating multiple productions that are different one and another will takes time, and it won’t allow them to do mass productions to cut the expense. If you find a woodworking factory in Indonesia that produces more than one different type of product, then you can assure that the products are made by their subcontractor under their name. But it doesn’t mean that the product is less in quality because the product also has to complete every steps and test that the main factory gives to maintain the quality of the products.

Duties of Woodworking Factory in Indonesia

Some of you might not be familiar with woodworking factory duties; you may think that each factory will build numerous products and send them to the local shop. However, it is not as easy as it seems because each factory only produces one single type of product to maintain its ability to mass produce the product. Manufacturing more than one type of product will reduce efficiency and give more cost to production because both labor and machinery need to be adjusted to meet the requirement of production. Usually, one woodworking factory in Indonesia will only produce one type of product in a different design, but the basis of the product is still the same; they also use the same materials to avoid any machinery failure as a result of multiple adjustments. Since the woodworking factory only produces one type of product, what does the company usually do in a daily basis?

The duties of a woodworking factory usually consist of:

- The first duty of the factory is to make the blueprint of the product, and it is considered the basic procedure that the company should complete before they even make any product. The blueprint will determine the structure of the product, the design, as well as the program system that will be used on the machinery to shape the materials, and it will also determine the job of each person in contributing to mass production. Without the present blueprint, a factory cannot run its productions because they don’t have the picture of the product they have in mind.

- After completing the blueprint, the company also needs to set up the machine, and it is possible that the company will need to spend all of its money to buy the latest technology to support its production. The factory usually buys a machine with multiple tasks that can record different tasks on its system.

- Soon after the machine has been set up, production can also be started. During the application of the machine, the engineer will install software and any other application to make the machine able to create a specific shape. When it is done, all you have to do is to prepare the material and process it for the machine; soon after, the machine will do the task automatically and produce the shape that has been asked.

- After shaping the materials and then come to assembling the parts, the engineer needs to make sure that there is no error during the production of the parts. Make sure that the machine does not make any strange noise to ensure its optimal capability in manufacturing the parts to avoid any product failure. As parts are completed then, it is the task of the artisan to assemble the products one by one because the machine cannot do this task as precise as the artisan; although the factory mostly relies on the machine, they still need the help of professional artisan to assemble the product to maintain its standard quality.

- After building a product, several tests and checks should be conducted to meet the market standard; professionals and machines also do it. These people will check whether there is some damage and production failure that may affect the quality of the products.

- The task of the woodworking factory does not end until that because they also have to make the delivery to the local store or export. Conducting a delivery is much harder than you think because the products need to be in good shape, so the delivery system is also costly because some companies apply insurance for the delivered products. Some factories may choose to deliver their product in parts which make the local store play an important role in assembling the products. It is become common to find products that are categorized as DIY projects, but sometimes it can only be done by professional, which make the buyers have to spend more money on the services.

It can also be assumed that the duty of a woodworking factory in Indonesia is not only about making the products that were asked by the market; they also have to design them, manufacture the products, and test and ship them to the consumer. Contact us immediately if you are looking for a woodworking factory in Indonesia. We have a lot of experience with the export markets in delivering wooden doors and furniture.