A flush door is commonly found in houses, both for modern and traditional interior design. Some people choose this type of door because of the smooth surface on the door that fits any house, while the rest choose this door because it is available everywhere, so it can be easily purchased. However, do you know how the door is made and then supplied a flush door factory to many local stores? Many of us know that a flush door is made from plywood; however, it is not all true since it often combines with timber frame and MDF; sometimes, the hollow part of the door is filled with cardboard.

Table of Contents

Making The Flush Door

How does the flush door factory make their product? Some detail about the manufacturing of flush doors can be seen on the internet, while this article will describe the steps in words.

- The material to create a flush door is plywood and timber. Each material is required for a different purpose; timber is used for the core of the door. Before applying the wood to the door, we have to make sure that the timber is free from decay and insect attack; it needs to take preservative treatment that includes soaking the timber with a mixture of borax and boric acid. Additional material that will be used in making a single flush door is face veneers, adhesive, cross-band, and particle board.

- Before cutting the materials, the flush door factory needs to decide the type of doors that they want to make. Do they want a solid core, hollow or cellular core? They also need to determine if the type of door that they want to build is a decorative or a non-decorative one. After deciding the type of door that they want to build, they also need to decide the size of the door as well as the thickness.

- After cutting the wood into several parts to support their purpose, then the wood needs to be assembled and constructed to be shaped as a door. During construction, the flush door factory needs to prepare stiles and rails, leveling, face panel, lipping, rebating, opening for glazing, and Venetian. All of the parts of the door need to be assembled in their place; each of them will have its own size to fit each other; failing in measuring the parts means a terrible disaster that may lead to great failure.

- The next step that should be done by the flush door factory is fitting, and it is required to conduct precise measurements on locks and laches. Usually, the lock fitting will only be conducted during the purchasing; it should not be made earlier because each people has a different preference. If there is no special requirement, the hole will be applied on standard measurement.

- After the fitting come the workmanship and finishing, it insists on sanding and painting the surface to create a smooth and even texture. Polishing and vanishing may also include in the treatment, but it also includes the priming process as the basic coat. It is then followed by decorating the door when the type of door that has been purchased is a decorative one.

- After workmanship and finishing, it doesn’t mean that the task of the flush door factory has been completed; because they also need to do the testing. There are several tests that should be taken by the product, including an end immersion test, knife test, adhesion, and type test. The product should take these entire tests to ensure the quality of each of them; after the testing completes then, the manufacturer can ship them to the local store or the consumers.

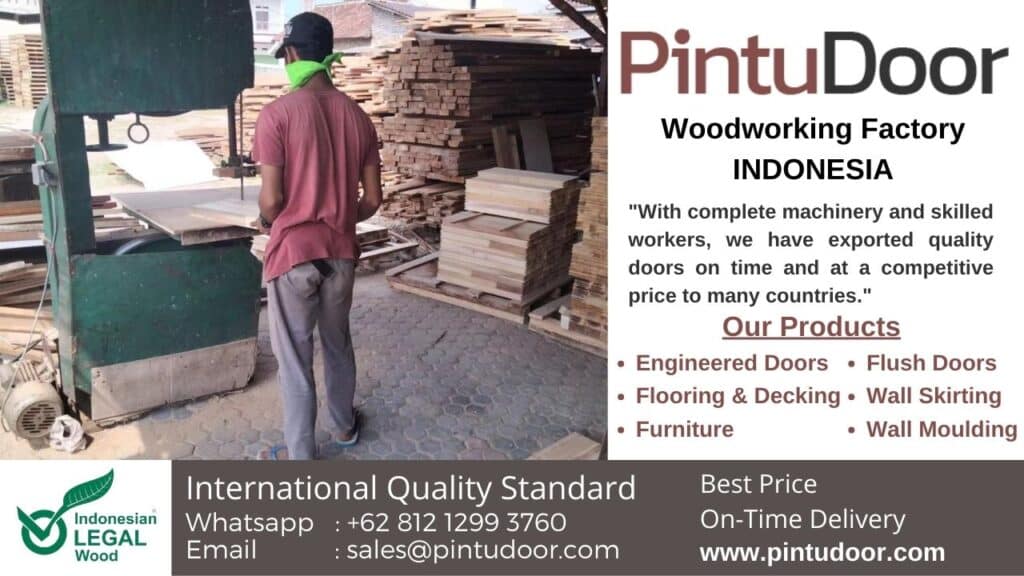

It needs to note that each factory has its own way of manufacturing the flush door; it doesn’t mean that all factories follow the same steps and procedures. The processes can also be different from one another, and what has been explained above is only applicable to a flush door with a hollow core. It won’t be the same for those with a solid and cellular core. Some factories produce more than one type of flush door, and the size may be varied, so it is important to decide the type that you prefer and mention the size before purchasing one. If you are looking for solid engineered doors and flush doors, check manufacturers in Indonesia; we are known for our good woodworking skills and low price.

Flush Door Factory, General Door Sizes And Models

Flush door factory is specialized in producing wooden flush doors for mass production; they usually don’t produce any other type of products; they only produce one kind of door that is different in terms of sub-type, color, and size. The size of the door is usually fixed internationally, so whether you buy the product from a different company but the size of the door that you can buy is still the same unless you make a special arrangement with the factory to meet your requirement.

Not only does the size that is similar, but also the design; most of the factories prefer to make a smooth straight design of door which is suitable with the plywood material that they use for manufacturing the products.

The Size Of Doors From Flush Door Factory

The type of flush doors that you can find in the local store and any other flush door factory are varied in size; they usually range from 25 mm to 45 mm; which means at least there are eight different sizes that you can buy. However, there is a general understanding that the general sizes of flush doors that the factory can manufacture are height: 78”, 82”, 96”, width: 24”, 27”, 30”, 33”, 36”, 42”, 45”, 48”.

Knowing the general size of the door is required when you want to replace the door on your house because if the door space of your door does not meet the general size of the mass production doors, then you probably have to make special inquiries on the factory which is more expensive than the general door.

Customizing The Door Is It Possible

Making a special arrangement to create your own door is not a possible thing to do because some flush door factories accept customized doors for different purposes. The factory does not only accept an order to change the door size to meet the customer’s need but also makes any other special arrangements far from the original mass production door. You can also add some customized or additional features to your requested door; it includes waterproof, ready-to-fix, polished, and Custom design.

Each factory may also offer different kinds of raw materials that will be used for the flush door, depending on your request. The material for the flush door is mostly made from layers of plywood, but you can also find the door is made from different materials, including oak, cherry, maple, eucalyptus and hemlock, and solid wood. Although the flush door size, design, and material are usually fixed internationally, you can still make changes to your order because this type of door is easily customized.

Durability Of Flush Doors

Buyers choose this type of door because the price is lower than any other door; the low price comes from the less material cost that is spent to build this type of door. A flush door is a durable door, as long as you consider using it for the interior only, but it may be different when you apply the door in a place where the door is easily exposed to rain and sun. Most of the flush doors which are produced by the flush door factory are water resistant, and it is also common to find a door that is heat resistant. As an indoor door, the flush door needs less maintenance than any other type of door, especially from insect attack, because this door has been processed and tested to ensure that there is no insect that inhibits the wooden materials of the door.

You might have already known that flush doors are made into several designs, some of them are straight and smooth, but others may be decorative; the inside of the flush can also be hollow or hardcore. Each flush door factory may provide you with these types of flush doors that you can possibly think of. Although the design, size, and texture of the door may seem different on the outside, the basic manufacturing process is still the same.